In the first place, the matrix of cases and load situations to be simulated during a machining process, which is carried out using CNC technology, has been defined.

From these analyzes, stresses and displacements of the simulated parts have been obtained to know their state in the CNC machining process.

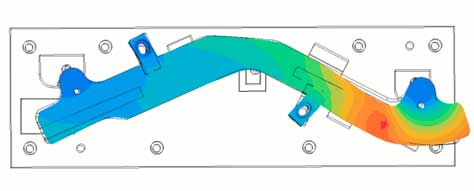

In the first piece of study, the supports by means of flanges of the piece to the machining platform have been analyzed. Once the simulations were carried out, different supports with high stress values were observed, for which reason another distribution of the supports was proposed and calculated, generating a lower stress level in them. In addition, thanks to this new proposed support system, the stresses in the flanges are reduced by up to 136% and the deformation of the piece is limited, which is quite important when machining it to avoid possible permanent deformations in the piece. that may generate a failure in your quality review.

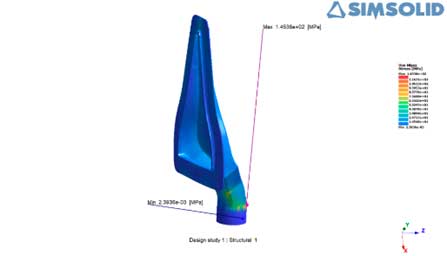

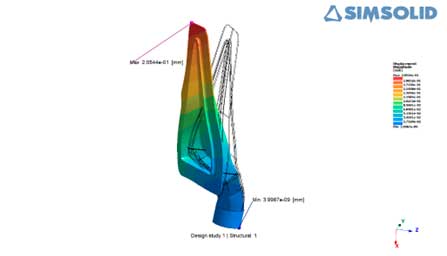

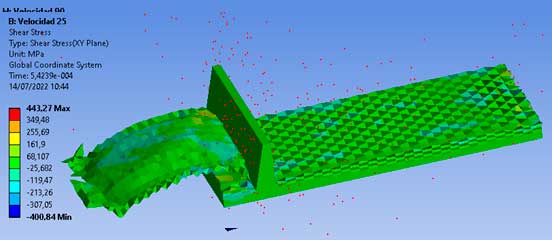

In the second simulation, shown in the image above, the calculation of the piece from additive manufacturing has been made. In this piece, through static loads that simulate the impact of the tool on the piece, the deformations and stresses in the piece have been analyzed. After these simulations, it has been verified that the part, during its machining, is not prone to considerable damage that could plasticize any area of its geometry, so the machining route in an anticlockwise direction with a support in its lower part is suitable. so that the piece can be machined without producing plastic deformations.

Subsequently, dynamic simulations have been carried out to analyze the behavior of each of the cutting parameters referred to the CNC machining process. In this way, it is defined which combination of parameters is optimal in order to carry out more efficient machining.

In this study, the cutting speed of the tool has been analyzed, which affects the state of the final machined piece and its temperature, the depth of pass that has an effect on the generated burr and the effect of the final piece and the width of last. Two different machining routes have also been simulated in order to evaluate alternative routes. In this way, the cutting parameters that most affect the piece have been identified, generating a poor-quality surface after machining or those that generate temperatures in the final piece that can become problematic in the piece. It is concluded that machining in the wide part of the piece is more recommendable than in its longer part, as the surface of the final piece is of better quality and

as a lower stress state is generated in the piece.

It has also been concluded that as the cutting speed increases, the machining process is shorter in time, but the stresses generated on the surface of the piece make it very prone to deformation when a new one is machined. past as these stresses would try to break free and deform the piece.

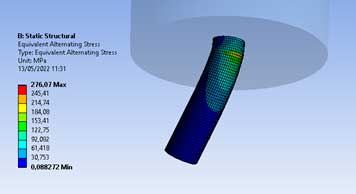

Finally, a study of the fatigue analysis of the tool has been carried out, in this case a milling cutter with a trochoidal cutting movement, where the weakest areas of the tool in terms of stresses and deformations can be observed.

This analysis is of vital importance since the tool is subjected to constant loading and unloading cycles, in this case, related to the removal of material called roughing. After the study, by identifying that the most stressed area is due to an area with singularities, it is concluded that the tool will not have problems during its useful life due to fatigue effects.